Railway Concrete Sleepers: What are they and why are they used?

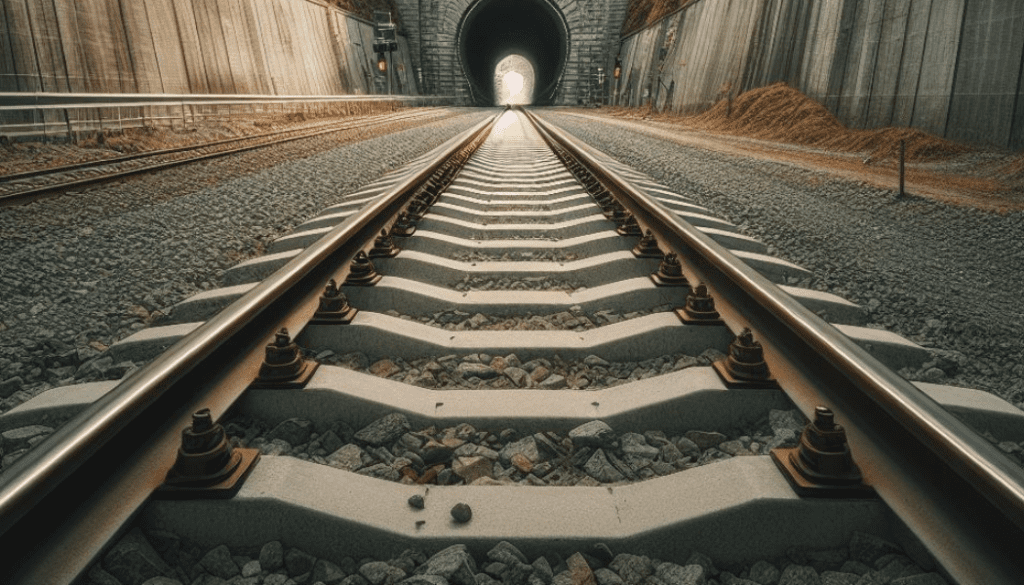

Railway concrete sleepers, also known as ties, are the horizontal elements that support the rails and keep them in place. They are essential for the stability and safety of the railway track. There are different types of sleepers, such as wooden, steel, and concrete. In this blog post, we will focus on concrete sleepers, which are widely used in modern railways around the world.

What are concrete sleepers?

Concrete sleepers are made of steel reinforced concrete, which is a composite material that combines the strength of concrete and steel. It can be either one piece of uniform or variable dimensions, or two separate blocks connected by a steel tie rod. Concrete sleepers are usually pre-stressed, which means that they are subjected to a compressive force before being installed, to improve their resistance to bending and cracking.

Types of railway Concrete Sleepers

There are different types of railway concrete sleepers, such as:

Prestressed concrete sleepers:

These are sleepers that are subjected to a compressive force before being installed, to improve their resistance to bending and cracking. They can be either one piece of uniform or variable dimensions, or two separate blocks connected by a steel tie rod. They are widely used in modern railways around the world, especially in high-speed, heavy-haul, and urban lines. Some examples of prestressed concrete sleepers are PCS-12, PCS-14, and B-58.

Post-tensioned concrete sleepers:

These are sleepers that are tensioned with steel wires or bars after being cast and cured. The tensioning force is applied through a jack or a hydraulic device, and the wires or bars are anchored at the ends of the sleeper. This type of sleeper has a higher initial prestressing force and a lower final prestressing force than the prestressed type. They are also used for high-speed and heavy-haul railways, as well as for special purposes, such as points and crossings. An example of post-tensioned concrete sleeper is the D&W type.

Why are concrete sleepers used?

Concrete sleepers have many advantages over other types of sleepers, such as:

Durability:

Concrete sleepers have a long service life, up to 40 years or more, and are resistant to weathering, corrosion, fire, and pests. They also require less maintenance and replacement than wooden or steel sleepers.

Stability:

Concrete sleepers are heavier and stiffer than wooden or steel sleepers, which means that they can better withstand the forces and vibrations caused by the trains. They also provide a more uniform support for the rails, reducing the risk of track deformation and buckling.

Economy:

Concrete sleepers are cost-effective in the long run, as they have lower life cycle costs than wooden or steel sleepers. They also save on ballast, which is the layer of crushed stone or gravel that cushions the sleepers and drains water from the track. Concrete sleepers have a wider base, which reduces the pressure on the ballast and the need for frequent tamping and renewal.

Versatility:

Concrete sleepers can be designed and manufactured to suit different requirements and specifications, such as gauge, load, speed, curvature, and geometry. They can also be used for special purposes, such as points and crossings, guard rails, switch expansion joints, check rails, level crossings, and dual gauge.

How are concrete sleepers made?

Concrete sleepers are made in factories, where the concrete is mixed, poured, and cured in molds. The molds are equipped with steel wires or bars, which are tensioned to create the pre-stressing force. The concrete is then steam cured to achieve the desired strength and durability. The finished sleepers are then transported to the railway site, where they are laid and fastened to the rails using clips, pads, or chairs.

Where are concrete sleepers used?

Concrete sleepers are used in many railways around the world, especially in high-speed, heavy-haul, and urban lines. Some examples of railways that use concrete sleepers are:

- The Indian Railways, which is the country’s largest supplier of concrete sleepers, with a total installed capacity of 4.85 million sleepers per annum.

- The European Rail Traffic Management System (ERTMS), which is a standard for signalling and train control that requires the use of concrete sleepers for compatibility and safety reasons.

- The High Speed 2 (HS2), which is a planned high-speed railway in the United Kingdom that will use concrete sleepers for its track infrastructure.

- The Shinkansen, which is a network of high-speed railways in Japan that uses concrete sleepers for its track stability and noise reduction.

Conclusion

Railway concrete sleepers are an important component of the railway track, as they provide support, stability, and durability for the rails and the trains. They have many benefits over other types of sleepers, such as wooden or steel, and can be adapted to different needs and conditions. Concrete sleepers are widely used in modern railways, especially in high-speed, heavy-haul, and urban lines, and are expected to remain the dominant choice for railway sleepers in the future.